Microfiber (microfibre) is synthetic fiber finer than one denier or decitex/thread, having a diameter of less than ten micrometres. A strand of silk is about one denier and about a fifth of the diameter of a human hair.

The most common types of microfiber are made variously of polyesters; polyamides (e.g., nylon, Kevlar, Nomex, trogamide); and combinations of polyester, polyamide, and polypropylene. Microfiber is used to make mops,mats,cleaning cloth and other cleaning products.

The shape, size, and combinations of synthetic fibers are chosen for specific characteristics, including softness, toughness, absorption, water repellence, electrostatics, and filtering ability.

History

Production of ultra-fine fibers dates from the late 1950s, using melt-blown spinning and flash spinning techniques. Initially, only fine staples of random length could be manufactured and very few applications were found.Then came experiments to produce ultra-fine fibers of a continuous filament type: the most promising experiments were made in Japan in the 1960s and that leds to many industrial applications, including Ultrasuede, one of the first successful synthetic microfibers, which entered the market in the 1970s. Microfiber's use in the textile industry then expanded. Microfibers were first publicized in the early 1990s, in Sweden, and saw success as a product in Europe over the course of the decade.

Uses in our field of cleaning

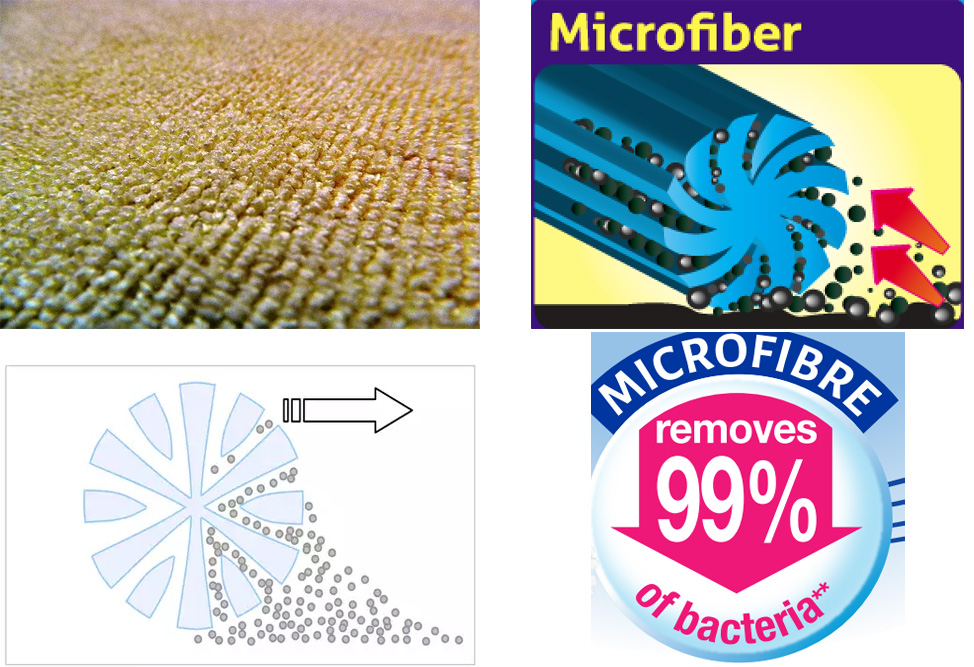

In cleaning products, microfiber can be 100% polyester, or a blend of polyester and polyamide (nylon). It can be either a woven product or a non woven product, the latter most often used in limited use or disposable cloths. In the highest-quality fabrics for cleaning applications, the fiber is split during the manufacturing process to produce multi stranded fibers. A cross section of the split microfiber fabric under high magnification would look like an asterisk.

The split fibers and the size of the individual filaments make the cloths more effective than other fabrics for cleaning purposes. The structure traps and retains the dirt and also absorbs liquids. Unlike cotton, microfiber leaves no lint, the exception being some micro suede blends, where the surface is mechanically processed to produce a soft plush feel.

For microfiber to be most effective as a cleaning product, especially for water-soluble soils and waxes, it should be a split microfiber. Non-split microfiber is little more than a very soft cloth. The main exception is for cloths used for facial cleansing and for the removal of skin oils (sebum), sunscreens, and mosquito repellents from optical surfaces such as cameras, phones and eyeglasses wherein higher-end proprietary woven, 100% polyester cloths using 2 µm filaments, will absorb these types of oils without smearing.

Microfiber products used for consumer cleaning are generally constructed from split conjugated fibers of polyester and polyamide. Microfiber used for commercial cleaning products also includes many products constructed of 100% polyester. Microfiber products have exceptional ability to absorb oils, and are not hard enough to scratch even paintwork unless they have retained grit or hard particles from previous use. Due to hydrogen bonding, microfibre cloth containing polyamide absorbs and holds more water than other types of fibres.

Microfiber is widely used by car detailers to handle tasks such as removing wax from paintwork, quick detailing, cleaning interior, cleaning glass, and drying. Because of their fine fibers which leave no lint or dust, microfiber towels are used by car detailers and enthusiasts in a similar manner to a chamois leather.

Microfiber is used in many professional cleaning applications, for example in mops and cleaning cloths. Although microfiber mops cost more than non-microfiber mops, they may be more economical because they last longer and require less effort to use.

Microfiber textiles designed for cleaning clean on a microscopic scale. According to tests using microfiber materials to clean a surface leads to reducing the number of bacteria by 99%, whereas a conventional cleaning material reduces this number only by 33%.Microfiber cleaning tools also absorb fat and grease and their electrostatic properties give them a high dust-attracting power.

Microfiber cloths are used to clean photographic lenses as they absorb oily matter without being abrasive or leaving a residue, and are sold by major manufacturers such as Sinar, Nikon and Canon. Small microfiber cleaning cloths are commonly sold for cleaning computer screens and eyeglasses.

Rags made of microfiber must only be washed with regular laundry detergent, not oily, self-softening, soap-based detergents. Fabric softener must not be used. The oils and cationic surfactants in the softener and self-softening detergents will clog up the fibers and make them less absorbent until the oils are washed out. Also, since microfibre cloth attracts much soil and holds water tightly, it provides an ideal nutritional environment for various microorganisms.

In our ranges,many products are made of Microfiber, Flat Mops,Dusters,Window Washer,Cleaning Cloth,Cleaning Mits,Floor Mats etc. Welcome to check our quality Microfiber Cleaning Items.